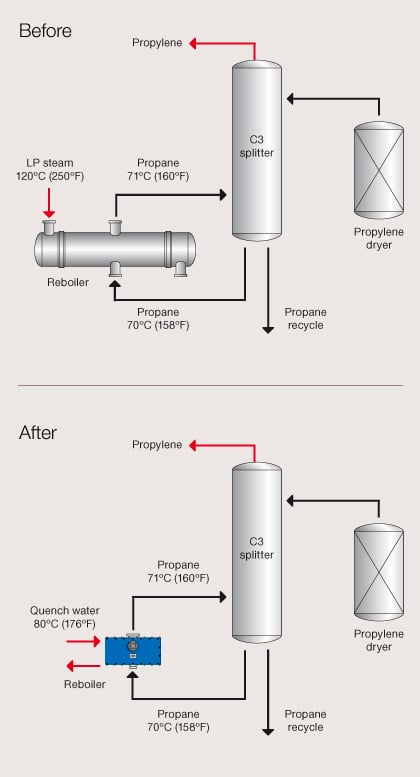

C3 splitter reboiler

Save steam with Alfa Laval heat exchangers

Low-pressure steam is a common heat source for C3 splitter reboilers. Using waste heat in quench oil or quench water is a much more economical solution.

A revamp like this is more or less impossible using shell-and-tubes. The required heat transfer area would be very large, making both available space and costs limiting factors.

However, with an Alfa Laval Compabloc heat exchanger in this position the problem is solved.

The high thermal efficiency of a Compabloc gives it a very compact size. A Compabloc occupies a fraction of the space of a comparable shell-and-tube, and the installation footprint is often 50-80% smaller.

Example

Exchanging an existing shell-and-tube C3 splitter reboiler for a Compabloc in a standard-sized plant gives you the following savings:

- Increased heat recovery: 3.8 MW

- Energy savings: €1,140,000 fuel or steam

- Reduced cooling-water temperature, fixed flow 1,000 m3/h (4,400 gpm): 3°C (5.4°F)

- Reduced cooling-water flow, fixed ΔT = 10°C (18°F): 300 m3/h

(1,320 gpm) - Reduced CO2 emissions: 5,600 tonnes/year

Using a more efficient heat exchanger as reboiler allows you to use quench water as heat source instead of steam.