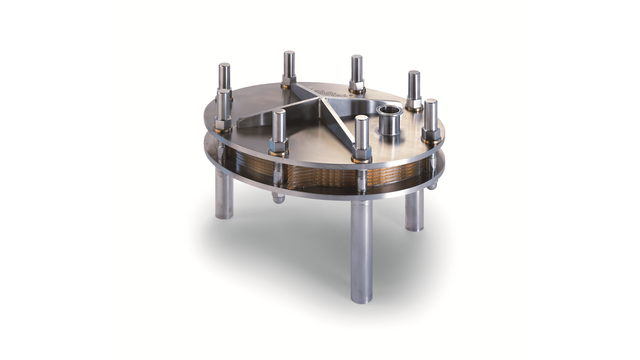

LabStak M37/38

The Alfa Laval LabStak® M37/38 is a flexible plate-and-frame test unit for ultrafiltration and microfiltration membrane processes. The unit utilizes support plates and flat sheet membranes of the same size as our full-scale membrane filtration modules. This makes the Alfa Laval LabStak® M37/38 a popular choice for process development, up-scaling, membrane testing, quality assurance and small-scale production. Optional plate sets are available for feeds of different viscosity / solids content

Handy and flexible

The Alfa Laval LabStak® M37/38 is designed to provide quick and precise evaluations in laboratories and other test facilities, while keeping equipment and set-up cost to a minimum.

This flexible unit, which is designed for plate-and-frame operation, can be fitted with the full range of flat sheet membranes available from Alfa Laval for ultrafiltration and microfiltration.

Option

For the LabStak® M37/38 Alfa Laval offers alternative plate set configurations which can be selected according to use.

- M37 plate set

For highly viscous liquids - M38H plate set

High channel, for medium viscous liquids - M38L plate set

Low channel, for low viscous liquids

Alfa Laval LabUnit M37/38

The Alfa Laval LabUnit M37/38 is a fully integrated system comprising an Alfa Laval LabStak® M37/38 unit complete with necessary pump, valve, heat exchanger and instrumentation.

The Alfa Laval LabUnit M37/38 is a fully integrated system comprising an Alfa Laval LabStak® M37/38 unit complete with necessary pump, valve, heat exchanger and instrumentation.

Benefits

- flexible membrane areas from 0.11 m² to 1.05 m²

- simultaneous testing of up to seven different membrane types

- quick and easy exchange of membranes

- high operating temperature (up to 80°C)

- can be coupled to the by-pass stream of an industrial plant

- different channel height options to optimize flow and pressure

- low internal volume

- flexible system design

- flow pattern similar to that of larger modules

- all components in compliance with FDA regulations, allowing use within food and pharmaceutical processing applications

运行原理

阿法拉伐的板框式模块设计有横跨膜表面的开放通道。进料流/滞留物流过这些开放通道。

膜本身由带有许多槽的中空板支撑,这些槽可收集渗透液,并通过渗透液收集管从模块中排出。

v板框式模块在锁环或锁条的帮助下使用膜本身将进料/滞留物密封,防止其混入渗透通道。这也避免了板组(plate stack)本身的任何泄漏风险。