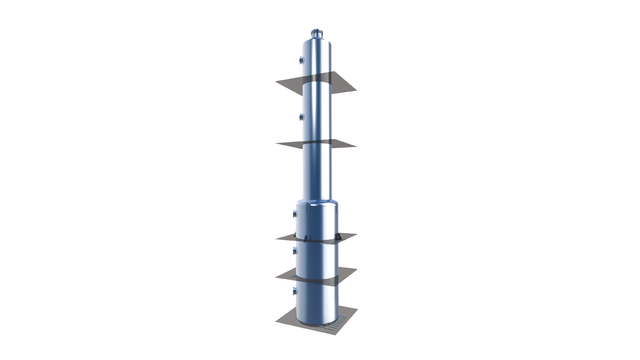

SoftColumn 软塔

At Alfa Laval, we don’t just make do with traditional deodorization thinking – we develop new and better ideas that later set the standard for the whole industry.

Deodorization is such a crucial part of edible fats and oils processing that the only way to really get ahead – and stay there – is to use the latest technology and the best equipment.

Alfa Laval’s patented breakthrough in applying thin-film technology to modern deodorization processes opens up important opportunities for taking your processing efficiency to a new level. It enables you to use less steam and to process the oil at lower temperatures. This results in more gentle, effective treatment that greatly benefits the quality of your fats and oils.

The Alfa Laval SoftColumn™ deodorization concept is also designed to be extremely versatile. Separate stripping and retention sections provide a wide range of options for implementing the most efficient deodorization solution currently available – both in new installations and when extending and updating existing fats and oils processing installations.

运行原理

从脱气开始

在加热油之前,必须在真空下除去空气(除气)以通过防止氧化来保护产品的质量。 离开脱气机后,油在特殊的换热器(即节热器)中通过离开除臭塔的热油进行再生加热。 这将确保从热油中回收尽可能多的热量。 油随后进入最终加热器,在该加热器中,通常使用高压蒸汽将油正好加热到除臭所需的温度。

汽提和保留

当油达到指定温度时,将其输入除臭塔,这是用于对食用油脂进行除臭的主要组件。 这样的除臭塔可以由汽提段和保留段组成。 当油通过汽提段时,它会受到真空和蒸汽的共同作用,由此除去比油本身的蒸气压更高的挥发物,包括游离脂肪酸 (FFA)。 如果存在这些挥发性杂质,食用油的风味、气味和稳定性会受到影响。

油随后在保留段中保留一定的时间以进行热处理(称为热漂白),目的是处理不良色素并确保最终产品的稳定性。 油在保留段中保留的时间长短在很大程度上取决于所需的产品规格。

冷凝除去的杂质

已从油中除去的挥发性杂质通过再循环和冷却的馏出物在所谓的洗涤塔单元中冷凝。 洗涤塔可以放在汽提段的顶部,也可以作为单独的容器建造。

冷却

最后,油分两个阶段冷却。 首先在节热器中,然后达到指定的最终温度。 由随后经过抛光过滤,再输送到后续工艺(储存或包装)。