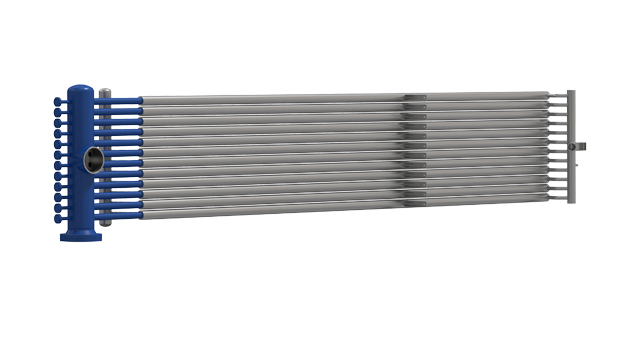

OLMI双管型初级急冷换热器

Olmi double-pipe primary quench exchangers (PQE) cool hot gaseous effluent from hydrocarbons cracking furnaces while generating steam. These highly efficient linear transfer line exchangers minimize the difference in thermal expansion between the inner and outer tubes to prevent cracking and fatigue. No thermal sleeve, short residence time of hot gas in the distributor and advanced welding also boosts ethylene yield.

Optimizing quenching processes for ethylene production

Alfa Laval Olmi double-pipe primary quench exchangers are highly efficient transfer line exchangers that mitigate or eliminate erosion, corrosion and fouling issues typically associated with primary quench exchangers.

Innovative design

Olmi double-pipe primary quench exchangers feature innovative design that effectively does away with common quenching problems. Here are the design innovations:

- No inner thermal sleeve in the inlet transition piece: (a) coke deposition on typical sleeve-to-inner pipe discontinuity is avoided, (b) no risk of sleeve deformation. This leads to longer lifetime and higher reliability.

- No refractory in the transition piece: (a) degradation of refractory along time and (b) possible defects in the refractory layer are avoided.

- No gas-side discontinuity from inlet piece to inner pipe; therefore, no coke build-up and local erosion.

- The most critical weld (inlet transition piece to inner pipe) is done by a welding from inside the piece (from inside the bore – “Internal Bore Welding” I.B.W.), without crevice points and fully x-ray inspectable. This weld results also fully immersed and well cooled by circulating water. There is no limit to the life of such welding (longer lifetime/higher reliability).

- The inlet transition piece is machined out from a solid Alloy 8811 forging or equivalent. This means high manufacturing quality. This also means high resistance to corrosion and erosion action of water at inlet.

- The inlet water nozzle is flushed with the inlet transition piece: no risk of fouling deposition and dead zones.

- Efficient cooling of the inlet transition piece eliminates risk of high creep/fatigue stresses (longer lifetime) and temperature peaks in local areas.

- Residence time of the cracked gas in the system is kept as small as possible; this improves the process yield.

- Possible use of special/patented baffles in the water inlet zone improves self-cleaning and cooling action by water.

- Differencial thermal expansion between inner and outer pipes is drastically reduced by proper shape on inlet and outlet transition pieces.

- Smoothed shape of the inlet trransition piece eliminates local high thermal-mechanical stresses

4 years without any defects and we have gotten so much income from their excellent quality. Yu Hengdu, Vice manager, China

Built to last

Extremely durable, Alfa Laval Olmi double-pipe primary quench exchangers are engineered for reliable operation and durability. Design features that make long service lifetime possible include:

- High manufacturing and inspection quality

- Mild operating metal temperatures and stresses

- Minimization of coke build-up and erosion on gas-side

- Self-cleaning on shell-side