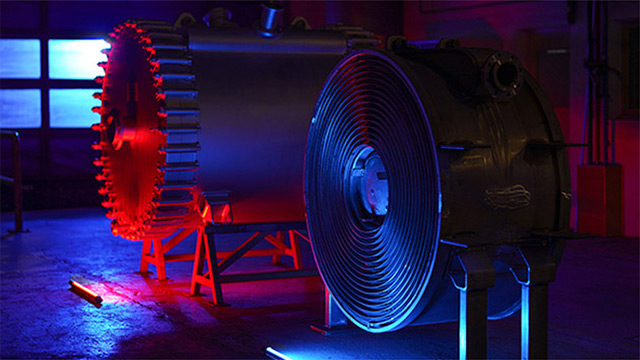

Welded spiral heat exchangers

Alfa Laval spiral heat exchangers are designed to handle the toughest heat transfer challenges. Whether it’s frequent fouling from dirty media, or limitations from pressure drop and floor space, they are the ultimate problem solver for liquid-to-liquid and two-phase duties. The robust, efficient and compact designs keep both installation and maintenance costs extremely low, and they have a proven reputation for almost never fouling up.

Improving sustainability with Alfa Laval’s spiral heat exchangers

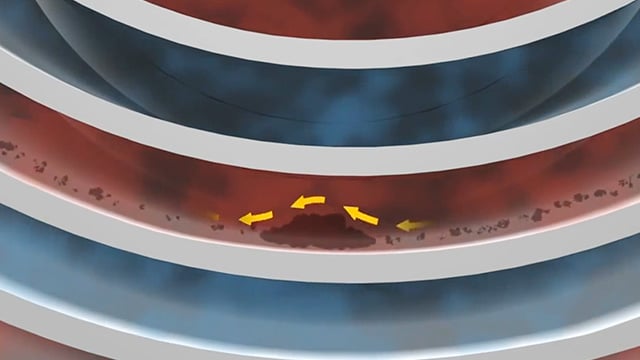

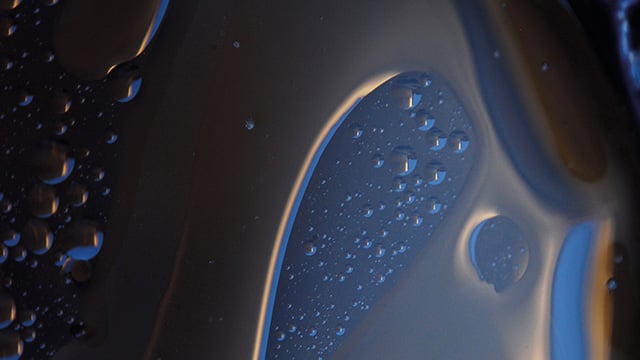

- Minimal fouling, or clogging, in duties involving very dirty, highly viscous or particulate media, ensures uptime

- Easy-to-open design makes cleaning quick and simple, ensuring low maintenance costs

- Reduced pipework and steel structures means lower installation costs

- Increased energy savings and reduced emissions thanks to thermal efficiencies 2-3 times higher than comparable shell-and tube exchangers

- Each unit is fully customized, offering the best thermal fit for the specific duty

Alfa Laval Spirals. The future starts here.

Are you looking for more uptime and twice the thermal efficiency of a comparable shell-and-tube? A spiral heat exchanger might be the answer. It has a quick payback time, with low installation and operating costs. Since 1962, Alfa Laval has helped more than 5,000 customers with their challenges, delivering more than 80,000 spirals. Could you be next?

Models

See details about SpiralPro for liquid-to-liquid duties or steam heater duties and find out more about SpiralCond for vacuum condensing and evaporation duties or in stacked column figuration.

How it works

How does a spiral heat exchanger work? Read about the working principle and design of our spiral heat exchangers and watch explanatory animations.

References

Hear from real-life customers how Alfa Laval spiral heat exchangers have helped them increase energy savings, cut emissions and solve issues with severe fouling in their processes.

Meet our experts

Join our heat exchanger specialists to learn more about the unique design of our spiral heat exchangers or how they resist fouling and blockage even when working with the dirtiest fluids.

Perfect for pyrolysis

An outstanding ability to handle heavily fouling fluids, combined with exceptional heat transfer efficiency, makes Alfa Laval spiral heat exchangers the perfect choice for pyrolysis oil applications. With spiral heat exchangers in your process, you get lower energy costs and reduced CO2 emissions, as well as longer uptime and increased production capacity.

Documents

文件

文件

Case stories

Unique features

Alfa Laval Energy news on Linkedin

Learn how our solutions, and the support we can offer, can help you identify new possibilities for both profitable growth and a positive environmental impact. On our showcase page you can keep up to date with our latest innovations and solutions and the work we do within clean energy, energy efficiency, and the circular economy.