扩大手工艺品生产规模以满足消费者需求

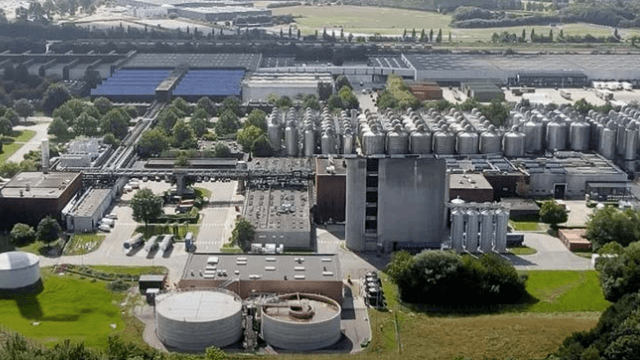

啤酒行业正朝着高端细分市场转型,这要求生产过程具备更大的灵活性和一致性。随着啤酒厂商 更关注融入多种原料的高端产品,他们需要能够适应变化并保持高品质的生产技术。随着消费者对独特啤酒的需求不断增长,离心技术在应对这些挑战中变得至关重要。

日期 2025-08-20The brewery industry is migrating into the premium segments, which means the production of products with a larger assortment of ingredients. To cater to this demand, technology-wise, centrifugation is providing brewers with flexibility and consistency in quality. These two factors are key for brewers to deliver the right product for the right market segment.

The trend of premium products is expected to grow over time, as consumers always seek something different. This growing demand places higher expectations on centrifugation technology. As such, the technology must evolve alongside the application to meet the rising challenges. The separator and its control systems must adapt to these changing needs.

Scaling craft beer production presents its own set of challenges. Unlike legacy products, craft beers are made in small batches with high specifications for the final product. These beers must be produced one after another in a very short amount of time. Thus, equipment needs to be flexible, able to make quick changes, and deliver consistent performance.

Alfa Laval’s centrifugation technology, with its unique Hermetic Design™, is the perfect solution for addressing these industry challenges. It provides brewers with the ability to produce premium-quality beer with zero oxygen pickup, all while minimizing utility consumption. This technology ensures that brewers can meet the high demands of the premium segment while maintaining efficiency and consistency.

Related products

Brew 750

- 最高可达1000升/小时

- Hermetic Design™几乎完全消除氧气吸附风险

- 低能耗

- 配备完整配套系统的分离器

- 浊度触发固体排放

- 通过进水浊度控制处理能力

- Siemens 或 Allen Bradley 自动化系统