格林斯博罗的 T.Z. Osborne 水回收设施采用阿法拉伐 Aldec G3 将污泥脱水能力提高了一倍 - 功率仅为原来的一半

T.Z. Osborne 水回收设施位于北卡罗来纳州格林斯博罗市,长期以来一直是该市污水处理基础设施的基石。在使用污泥脱水离心机二十多年后,该厂寻求一种现代化的解决方案,以提高吞吐量、降低运营成本并满足日益严格的排放法规要求,而无需进行大规模翻新或停机。用阿法拉伐 G3 卧螺离心机取代老化的污泥设备后,流量增加了一倍,所需的动力却减少了一半,聚合物用量也减少了。

日期 2025-11-06

Since opening in 1984 with a capacity of 20 MGD, the facility has undergone a series of strategic upgrades to meet growing demand and evolving environmental regulations. By 2021, T.Z. Osborne had expanded to a capacity of 56 MGD - a nearly threefold increase. Although the facility initially intended to replace its 25-year-old sludge dewatering decanters through an open bid process, the project was reframed after engaging with Alfa Laval’s water separation experts, Mark Schlitzkus and Sipke Verbeek.

Turnkey delivery to compress cost and time

The consultative approach of Alfa Laval’s experts addressed mechanical and process questions, supported by reference visits to similar installations. After thoroughly assessing the needs of Greensboro’s water reclamation facility, Alfa Laval proposed partnering with an experienced integrator and managing equipment and installation as a single package - reducing engineering overheads, implementation risk and total cost of ownership. Crucially, this approach enabled two decanter installations within a budget originally scoped for one, while also shortening the project timeline.

Alfa Laval developed a proven solution for our centrifuge needs. Seeing the solutions at several west coast installations helped my team better understand the unique opportunity for our sludge dewatering. We are now able to feed our incinerators with one centrifuge where in the past it took two. Heyward’s and Alfa Laval’s management of the project made this one of the best solutions we have experienced at TZO,” comments a representative from T.Z. Osborne Water Reclamation Facility.

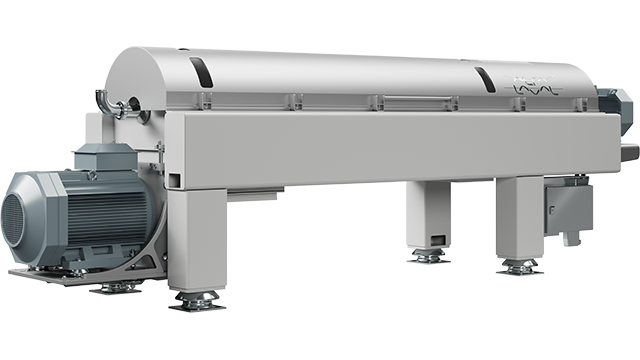

The plant selected Aldec G3 sludge dewatering decanters compact, high-performance machines engineered for low energy consumption and minimal operator intervention. Key feature innovations include SuperPond that enables a deeper pond for higher throughput and lower power, and PowerTubes that recover kinetic energy and further reduce energy use.

Results

- Flow capacity doubled per unit without expanding the municipal footprint, enabling operational flexibility across sludge management steps.

- Power consumption halved compared with the plant’s older units, supporting the city’s energy‑reduction goals.

- Polymer usage reduced, further lowering operating costs and environmental impact.

This was one of the best projects I have worked on in my 40 years in the business. It certainly had the right team in place on Alfa Laval’s side. I would advocate for that team on any retrofit,” says Tim Bishop, Regional Manager, Heyward Inc.