阿法拉伐的Brew 80助力斯德哥尔摩精酿啤酒商实现规模化生产成功

阿法拉伐技术助力一家瑞典精酿啤酒厂,确保其能够有效管理并最大化啤酒销售的巨大成功,提供了一套离心机解决方案,其投资回收期预计将少于18个月。

日期 2025-08-20With an annual production of 400,000 litres, Stockholm Brewing Co. has been a thriving independent operation since it was set up by three friends in 2012, and they were determined to seize the moment when they won a large contract with the Swedish state-run monopoly Systembolaget for its Italo Pils.

They needed to scale up swiftly and boost their flexibility to meet the contract requirements, while continuing to securely supply other products and customers, so a rapid increase in production capacity was essential.

The solution was Alfa Laval’s world-class beer centrifuge, Brew 80, designed specifically for craft brewers, and the results since the unit was installed in February 2025 have been stunning with a yield increase of up to 10% for their lager beers, and 25% for dry-hopped beers, while the tank time for the beer has been cut from 30 days to less than three weeks.

In fact, according to Stockholm Brewing’s Michel Wigardt, the results can be even more spectacular. “We have gotten out a batch of lager in 15 days with great flavour results,” he says. “So effectively, we have gotten one third more tank capacity because of the shorter times that a batch holds up a tank.”

The length of time required for the beer to mature in the settling tank has been cut to between two and four days instead of 10 to 20, giving added flexibility and allowing more time for production upscaling.

“We needed a lot more capacity quickly and we had been looking at getting a separator for some time and this was the final push,” says Michel, who has been with the brewery since 2013. “It has meant we can produce more beer, more stable beer and we can do it faster.”

“Now we are looking at getting an extra six or seven brews from a tank every year – from 10 to 16 or 17 – so even at this relatively early stage, the payback time could be quicker than we originally thought.”

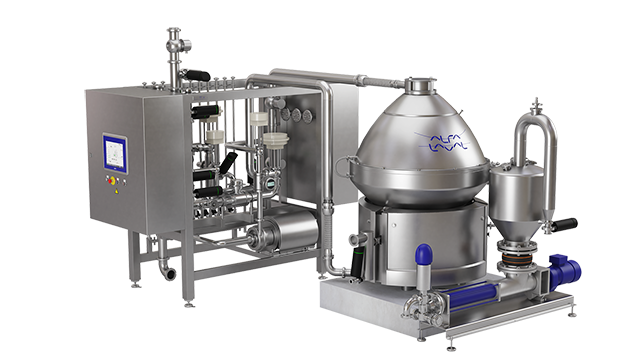

The Alfa Laval Brew 80 is a compact plug-and-play separation module with a design based on a top feed inlet with axial hermetic outlet offering a guaranteed maximum 10 ppb of dissolved oxygen pick-up.

“The separator has been easy to incorporate into our process,” says Michel. “If you compare it to a filter where you have a gazillion things that can go wrong, with this, you put beer in at one end and you get bright beer out of the other. It’s very, very easy.”

Crucially, as well as delivering dramatic results on the efficiency and speed of the process, it has ensured that the great aroma and taste of Stockholm Brewing’s portfolio of products are retained.

“Every now and again we might try something whacky with flavours, but generally our goal is to make beer that is accessible but still flavourful,” explains Michel. “We want something that is in balanced, approachable and drinkable.”

“Taste is crucial and what we have experienced from the Brew 80 is that it is non evasive in terms of flavour. In fact, for our bright beers, we want them to be bright in colour and taste, and run through the Brew 80 we are finding them brighter in both, and we can package and send out the beer on the same day that it has been separated, confident that it will taste and look how we want it.”

That confidence now extends to other styles of beer made by Stockholm Brewing, such as hazy beer, which brings a different challenge in the way it is produced.

“I had a concern about still getting the hazy appearance and still getting the stable product with the aroma and flavour profile I wanted,” says Michel. “But what we have experienced with the Brew 80 is that the flavour and aroma is very much there and in the glass it looks just as our customers want it to.”

The effectiveness of the Brew 80’s clarification performance and zero oxygen pick-up also means that the long-term shelf-life of the beers is boosted, as by preventing yeast autolysis derived off flavours in the brew over time.

For Michel the future of the business looks bright as he oversees the continued progress of the craft brewery situated by Stockholm harbour.

“When the brewery started out, it was about becoming the beer of choice for the people of Stockholm,” he says. “That is still the case, but now we are looking to move into the rest of Sweden and perhaps exporting our beer.

“Now that we can utilize our tank capacity much more efficiently thanks to the Brew 80, we can look to get more tanks, and the more the separator is used, the more it will pay itself off and we will benefit from the efficiencies.”

“I had only ever heard good things about Alfa Laval, their products and their services. This experience has reinforced that, and I know that if I need any support or assistance, then the team is just a phone call away – and, even better, they are located just around the corner!”