Marine refrigeration

Refrigerants are common in the marine industry, from chilling and freezing the catch on fishing vessels to air conditioning on cruise ships. Yet the refrigerant types are changing rapidly. Chlorofluorocarbon (CFC) and hydrochlorofluorocarbon(HCFC) refrigerants have given way to hydrofluorocarbon (HFC) refrigerants, and now many shipowners are exploring natural refrigerants like CO2. Alfa Laval has the heat exchanger solutions and expertise to support natural refrigerant choices.

Marine refrigerants in transition

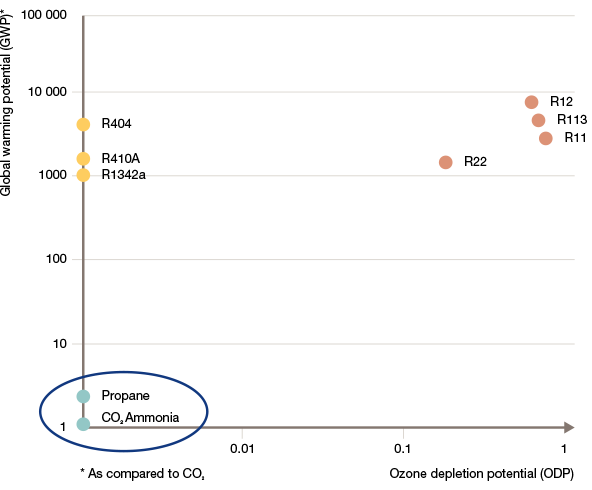

The move to more environmentally friendly marine refrigeration began with the ban on ozone-depleting CFC refrigerants. Today, 70% of the refrigerant in the merchant fleet – and especially on fishing vessels – is R22. R22 is an HCFC with much lower ozone depletion potential (ODP), but its global warming potential (GWP) remains extreme.

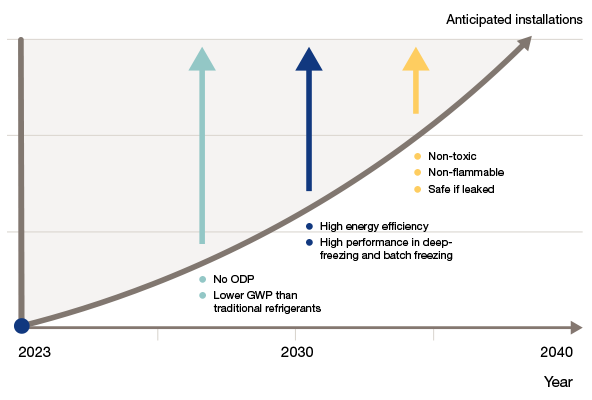

Now the industry is moving away from traditional options like R22, which has been forbidden as a refill refrigerant in Europe since 2015. The trend is towards natural refrigerants like ammonia (R717), propane (R290) and CO2 (R744), which have no ODP and a far lower GWP. The release of refrigerants from shipping is currently estimated at 8400 tonnes per year, which corresponds to around 2% of the industry’s greenhouse gas emissions (GHG).

CO2 as a marine refrigerant

Natural and increasingly economical options like ammonia, propane and CO2 can be used as refrigerants with high energy efficiency. CO2 requires robust heat exchangers that can work safely at higher pressures.

Heat exchangers for CO2 as refrigerant

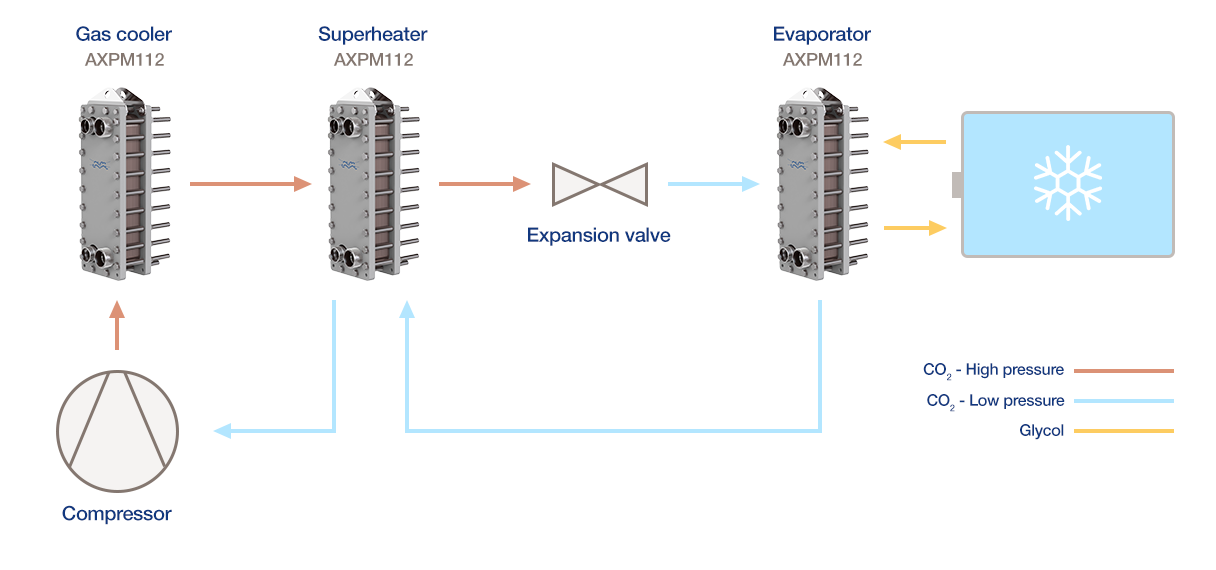

When using CO2 as the refrigerant, high pressures of 100–110 bar are required within the refrigeration system. This makes the copper-brazed Alfa Laval AXPM112 heat exchanger an ideal choice for safety. Part of the Alfa Laval AXPM line, the AXPM112 has exceptional pressure performance and efficiency due to its reinforced copper-brazed technology. Its high thermal performance results in lower operational cost, and its small hold-up volume means a lower investment cost for refrigerant. When retrofitting/upgrading, the AXPM112 is an optimal solution due to its small footprint.

Products

AXPM

Alfa Laval AXPM stands for “extreme pressure,” and that’s exactly what these brazed plate heat exchangers are designed to handle. Specifically engineered for subcritical and transcritical applications using CO2 (R744) as a refrigerant, the AXPM line can also support other fluids that require very high pressures. AXPM units are suitable for duties ranging from heat recovery, condensing and sub-cooling to gas cooling, suction gas heating and more.

服务

阿法拉伐海事服务

阿法拉伐海事服务遍布全球,全天候为您提供服务,帮助您延长正常运行时间,优化性能,让您真正高枕无忧。我们的网络随时待命,我们提供的服务可在设备的整个生命周期内为您带来可靠性、效率和合规性。

24小时全天候服务与支持

随时随地联系我们:

400 9976 911

china.info@alfalaval.com

我们的全球服务网络,包括服务中心、分销中心及现场服务工程师,随时准备为您提供支持。