Heating and cooling in the engine room

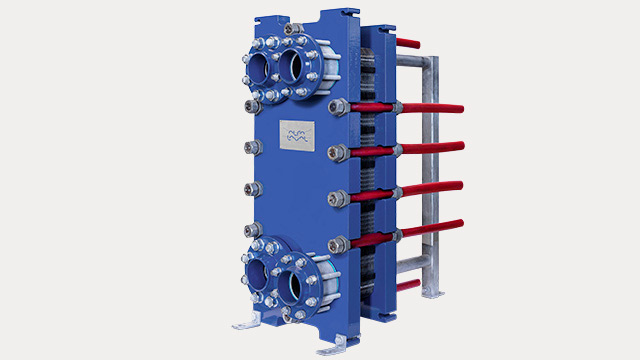

On a ship, there are many types of machinery with a cooling demand. When the heat energy cannot be recovered or utilized, the total costs of transferring it away from the machinery should be kept to a minimum. Alfa Laval can ensure a cost-effective central cooling system through our portfolio of innovative plate heat exchangers. Our gasketed plate heat exchangers have unique features that reduce the running costs for engine room cooling – and contribute to sustainability.

Central cooling system

Cost-efficient removal of excess heat

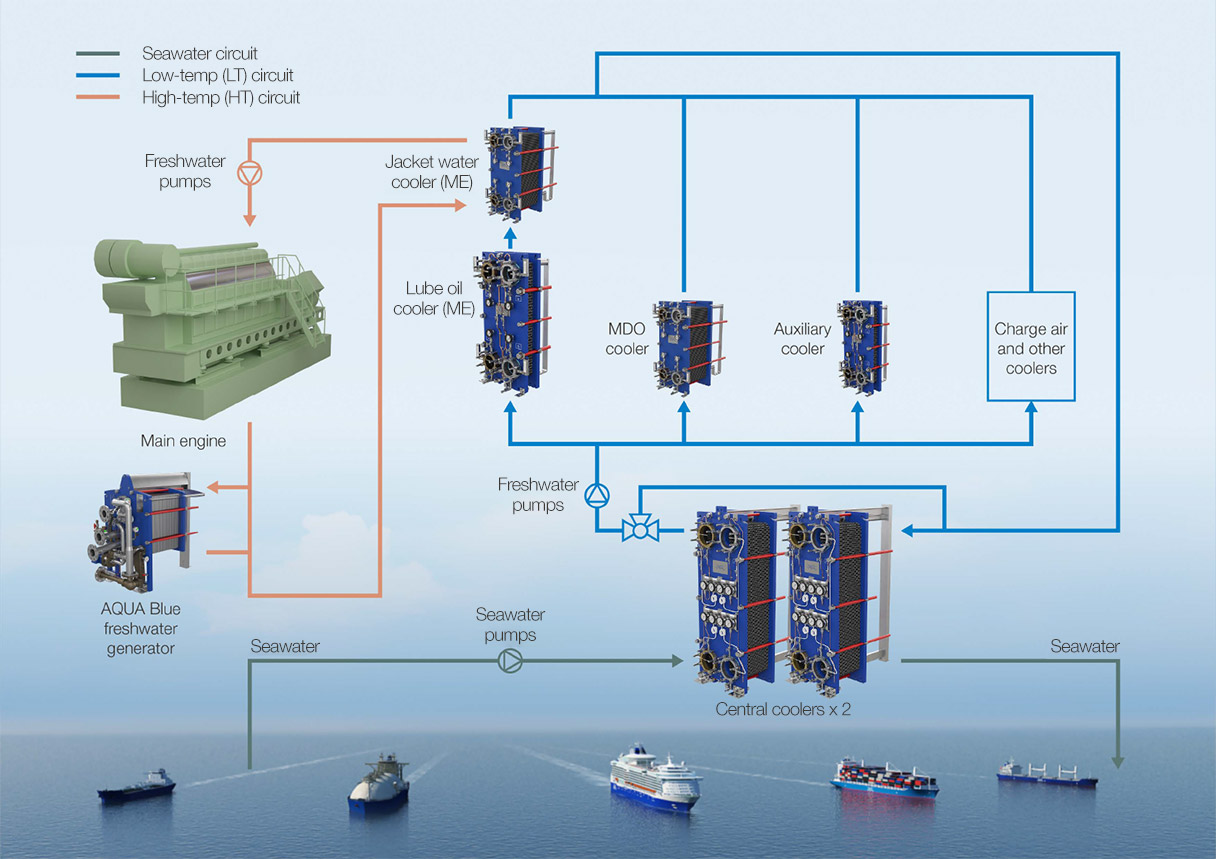

In the engine room, heat mainly needs to be removed from the jacket water cooler, lubricating oil cooler, diesel oil cooler and charge air cooler, along with the auxiliary engines and ancillary equipment.

The cooling flow of seawater is drawn from the sea chest. It passes through a coarse strainer to the titanium central coolers and thereafter overboard.

Fresh water is circulated through the central coolers, which are connected with a bypass regulation valve. The valve directs a portion of the fresh water through the coolers to maintain a constant temperature in the low-temperature circuit.

A portion of the excess heat generated in the jacket water circuit is used to generate fresh water in the Alfa Laval AQUA Blue freshwater generator.

Products

Services

阿法拉伐海事服务

阿法拉伐海事服务遍布全球,全天候为您提供服务,帮助您延长正常运行时间,优化性能,让您真正高枕无忧。我们的网络随时待命,我们提供的服务可在设备的整个生命周期内为您带来可靠性、效率和合规性。

24小时全天候服务与支持

随时随地联系我们:

400 9976 911

china.info@alfalaval.com

我们的全球服务网络,包括服务中心、分销中心及现场服务工程师,随时准备为您提供支持。