M30模块

The Alfa Laval module M30 is specially designed for reverse osmosis (RO) and nanofiltration (NF) tasks. Its unique features makes the M30 module from Alfa Laval the ideal choice for a large number of applications within the dairy, food, chemical, pharmaceutical, pulp and paper industries and for water treatment

Gets the water out

Where water removal or recovery is concerned, reverse osmosis is a superior method. Pure water can be separated from dissolved salts and solids. In a continuous mode, on a large scale and in a cost effective way.

Heat-sensitive products such as egg white, amino acids, pharmaceuticals, diluted foods and beverages can be concentrated at low temperatures. The costs are much less than for other, traditional processes - often the energy savings are as high as 50% compared to for example spray drying.

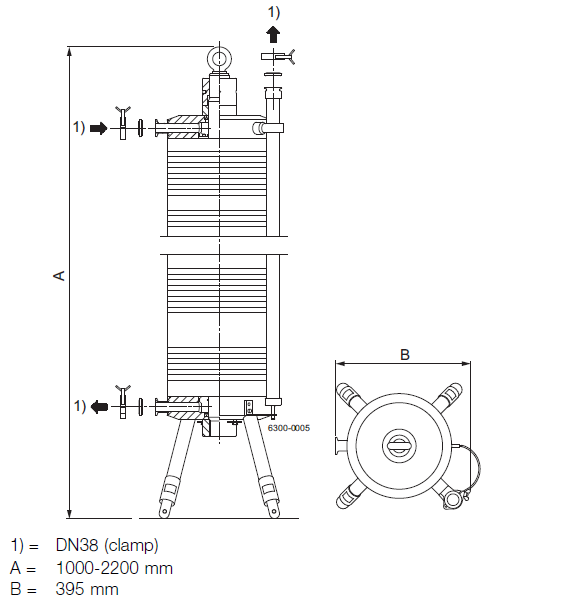

Plate-and-frame module, M30

The standard Alfa Laval plate-and-frame M30 module is made of stainless steel and rugged polymers. Held together by a single central bolt, this sandwich of spacers and membrane-covered plates is designed in a way that membrane flow channels form under hydraulic pressure.

The basic module is the same for all industries. However, the Alfa Laval module M30 can be scaled up or down and fitted with pumps for any purpose. This makes the M30 the ideal choice for a large number of applications within the dairy, food, chemical, pharmaceutical, pulp and paper industries and for water treatment.

The Alfa Laval module M30 is available with membrane area sizes up to 19 m² and it can operate at pressures up to 60 bar at 40°C and pH up to 9 (up to 12 for CIP). It can be equipped with the entire range of flat sheet reverse osmosis and nanofiltration membranes available from Alfa Laval.

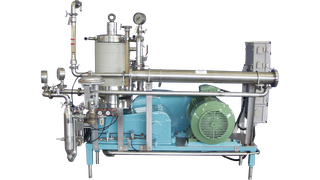

Alfa Laval PilotUnit Combi-50 RO/NF

The Alfa Laval PilotUnit Combi-50 RO/NF is a handy and versatile pilot-scale membrane system comprising an Alfa Laval plate-and-frame module M30 complete with necessary pump, valves, tank etc. It needs only power supply, compressed air, water and feed product to operate.

The Alfa Laval PilotUnit Combi-50 RO/NF is a handy and versatile pilot-scale membrane system comprising an Alfa Laval plate-and-frame module M30 complete with necessary pump, valves, tank etc. It needs only power supply, compressed air, water and feed product to operate.

Benefits

- sanitary design with all materials in compliance with FDA and EEC regulations

- easy cleaning by CIP (Cleaning-In-Place)

- low internal volume

- easy membrane failure detection and exchange

- low energy consumption

- chemical and thermal tolerances set by the membranes and the type of plate material

- concentration of heat sensitive and low molecular weight solutions

运行原理

阿法拉伐的板框式模块设计有横跨膜表面的开放通道。进料流/滞留物流过这些开放通道。

膜本身由带有许多槽的中空板支撑,这些槽可收集渗透液,并通过渗透液收集管从模块中排出。

v板框式模块在锁环或锁条的帮助下使用膜本身将进料/滞留物密封,防止其混入渗透通道。这也避免了板组(plate stack)本身的任何泄漏风险。

由于阿法拉伐板框式模块的设计,让客户可以更换单个膜而不影响模块的其他膜。

由于阿法拉伐板框式模块的设计,让客户可以更换单个膜而不影响模块的其他膜。